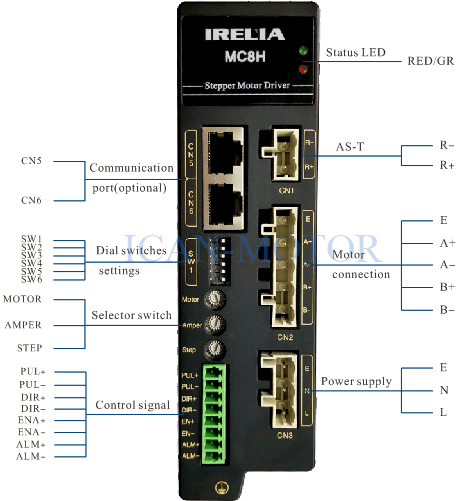

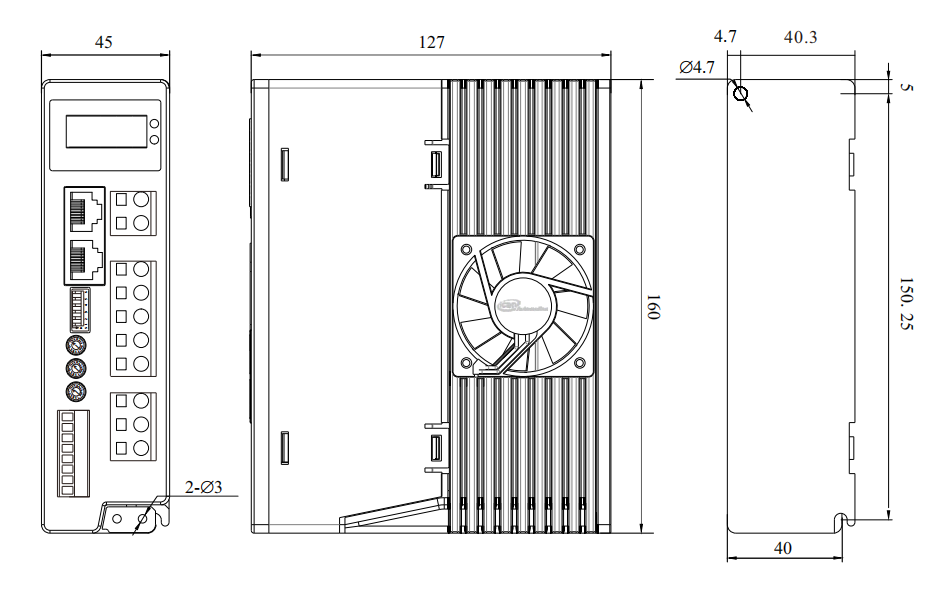

MC8H Stepper Motor Driver

Features:

High voltage Nema 42 stepper motor driver

8.0A, 85-265VAC

Support PUL/DIR and CW/CCW modes

Low noise, low vibration

Advanced DSP-based current control(0.5-8.0A) matches nema17-nema41

Easy setup via DIP switches for micro-stepping resolution(16)

We can offer stepper driver from 0.3A- 8.0A. Customization is also available.