What is brushless motor?

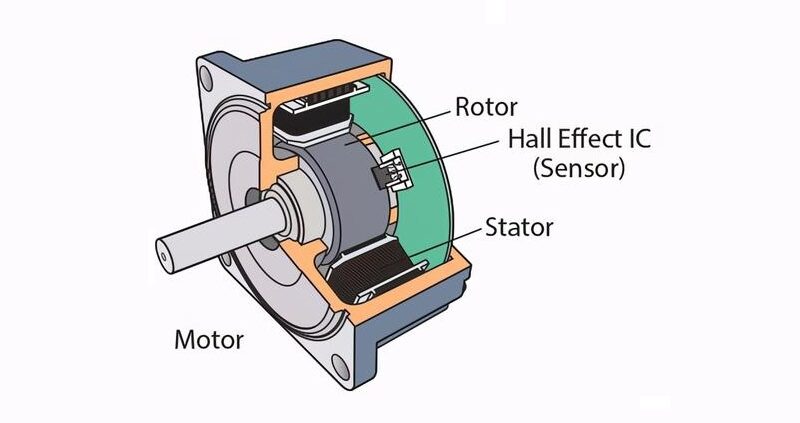

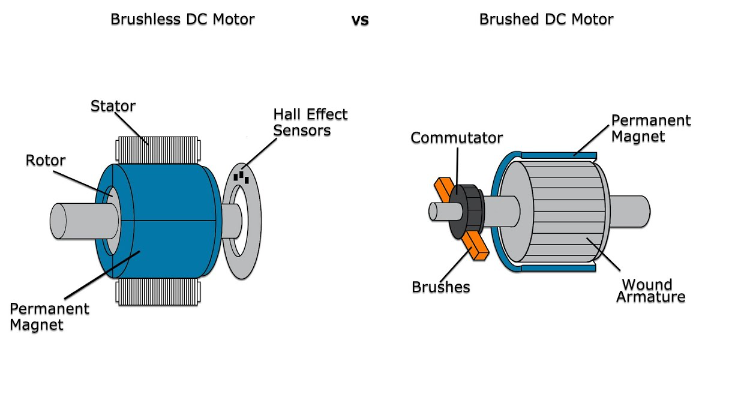

Brushless motor, is also known as brushless dc motor or BLDC motor . The construction typically consists of a rotor with permanent magnets, a stator with windings, and sometimes Hall sensors to detect the position of the rotor.

Bldc stator

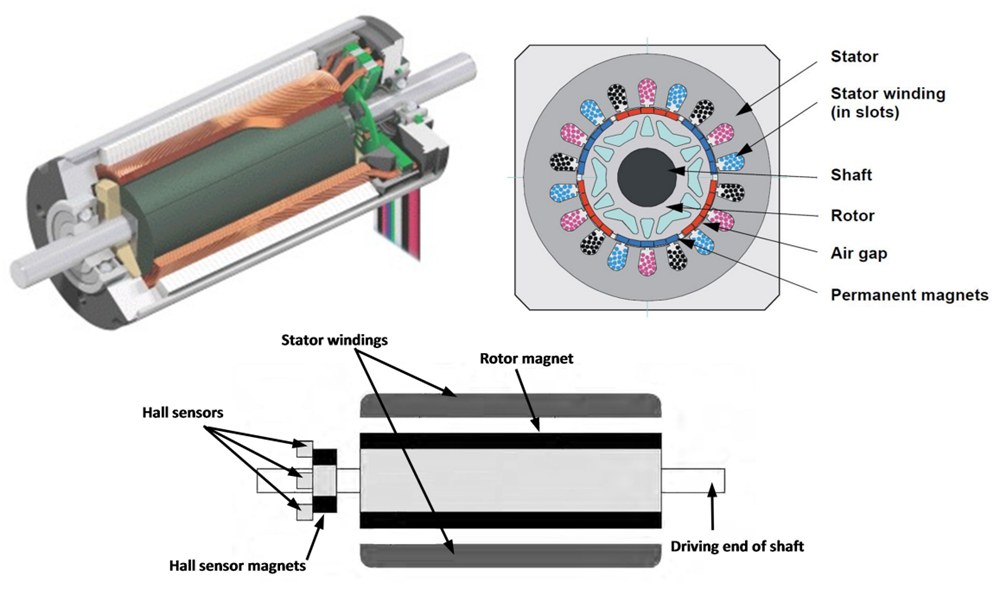

The stator is usually made up of stacked steel laminations with axial slots for winding. Most BLDC motors consist of three stator windings connected in a star or “Y” formation, which is 3 phase brushless motor. This design provides a more efficient and reliable operation compared to other types of motors.

Bldc rotor

The rotor part of a BLDC motor is composed of permanent magnets, most commonly rare-earth alloy magnets such as Nd, SmCo, and NdFeB. That is why BLDC is also permanent magnet brushless dc motor.

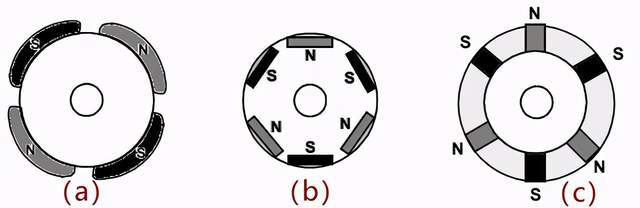

The number of poles can vary between 2 to 8 depending on the application, with the north (N) and south (S) poles alternating. The following figure shows three different arrangements of the magnetic poles:

(a)Magnets placed on the outer periphery of the rotor.

(b)Known as an electromagnetic embedded rotor, rectangular permanent magnets are embedded in the rotor core.

(c)Magnets inserted into the rotor core.

Sensored brushless motor

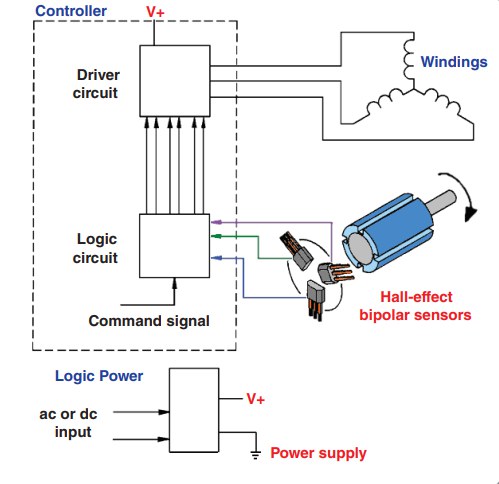

The BLDC motor has no brushes and requires electronic control for commutation.To make a motor rotate,the stator windings must be energized in a specific sequence, and the position of the rotor must be known to accurately energize a particular set of stator windings. To detect the rotor position , three Hall sensors are embedded in the stator, and convert position information into electrical signals.

When the north pole of the rotor approaches the south pole of the magnet, the Hall sensors produce a low output level. In contrast, when the north pole approaches the north pole of the magnet, the Hall sensors produce a high output level. This information is used to control the motor’s rotation and maintain the desired speed.

ICAN company offers best brushless motor with Hall sensors and can also customize sensorless bldc motor for you.

How does brushless dc motor work?

According to the Lorenz force law, a current-carrying conductor will experience a force when placed in a magnetic field. Due to the reactive force, the magnet will bear an equal and opposite force. In a brushless DC motor, the current-carrying conductor is stationary, while the permanent magnet is in motion. When the stator coil is energized, it becomes an electromagnet and produces a magnetic field.

Although the power source is DC, the switch generates a trapezoidal AC voltage waveform. Due to the interaction force between the electromagnetic stator and the permanent magnet rotor, the rotor continues to rotate. As the winding switches between high and low signals, the corresponding winding is energized as a north or south pole. The permanent magnet rotor with north and south poles aligns with the stator pole, causing the motor to rotate.

Brushless motor types

BLDC motors can be classified in various ways based on their voltage, power, performance. This diversity of classification allows for a wide range of applications for BLDC motors, making them one of the most versatile and efficient types of motors available today.

1.Classification based on voltage

Low-voltage refers to 12v brushless motor. It’s applications are power tools, toys, model airplanes, model cars, and smart homes.

Medium-voltage refers to 24v brushless motor and 48v brushless motor . It is widely used on electric bicycles, electric scooters, and electric vehicles.

High-voltage refers to 48v brushless motor and above such as 220v. It is generally applied to industrial control, power transmission, aerospace, and rail transportation.

2.Classification based on power

Small power brushless motor such as 250w bldc motor. These motors are small in size, high in efficiency, and have a long service life, and are widely used in household appliances, electric tools, toys, and other fields.

Medium power such as 500w brushless motor. These motors are widely used in machine tools, mechanical equipment, medical devices, and other fields.

Large power brushless motor with rated power between a few kilowatts and several hundred kilowatts: These motors have relatively specialized applications, such as wind power generators, ship propulsion motors, and so on.

3.Classification based on performance

High speed brushless motor

High rpm brushless motor are designed to operate at high speeds, typically 3000 rpm and above . They are suitable for applications such as industrial automation, robotics,printing machinery and medical equipment. Ican company’s brushless motor rpm is 1200-3000 rpm.

High torque brushless motor

These motors are designed to provide high torque at low speeds. They are suitable for applications such as conveyor system, electric vehicles,ships and lifting machinery.

Ican company offers BLDC motors of 0.66N.m to 80 N.m. Contact us to get more information now!

Diffirences of brushed and brushless motors

Brushless DC motor is a rising star in the market and is increasingly replacing brushed DC motors. Compared with brushed motors, brushless motors have more advantages:

Lightweight, thin, and high power

The rotor of the brushless motor uses permanent magnet materials, which makes it thin, lightweight, and high power. It can meet the demand for miniaturization of devices.

More energy-efficient

The rotor of the brushless motor uses permanent magnet materials, which reduces the secondary loss of the rotor and greatly reduces power consumption, helping to save energy.

Stable

Brushless DC motors are composed of a motor body and a driver. Because they operate in a self-controlled manner, they will not oscillate or lose step when the load changes suddenly.

Longer lifespan

Brushless motors can work continuously for about 20,000 hours, with a conventional lifespan of 7-10 years. Brushed motors can work continuously for about 5,000 hours, with a conventional lifespan of 2-3 years.

Maintenance and after-sales service

Brushed motors require carbon brushes to be replaced. If they are not replaced in time, they can cause damage to the motor. Brushless motors have a long lifespan, usually more than 10 times that of brushed motors, and require minimal maintenance.

Performance

Brushless motors use digital frequency control and have strong controllability. Brushed motors generally work at a constant speed after starting, and speed control is not easy. Shunt motors can also reach 20,000 RPM, but their lifespan is relatively short.

In general, the brushless motor price tends to be a lighter higher than that of brushed motor due to their more complex design and electronic commutation. However, brushless motors offer advantages such as higher efficiency and longer lifespan, which may justify the higher cost for certain applications. Ultimately, the choice between brushed and brushless motors will depend on factors such as performance requirements and budget.