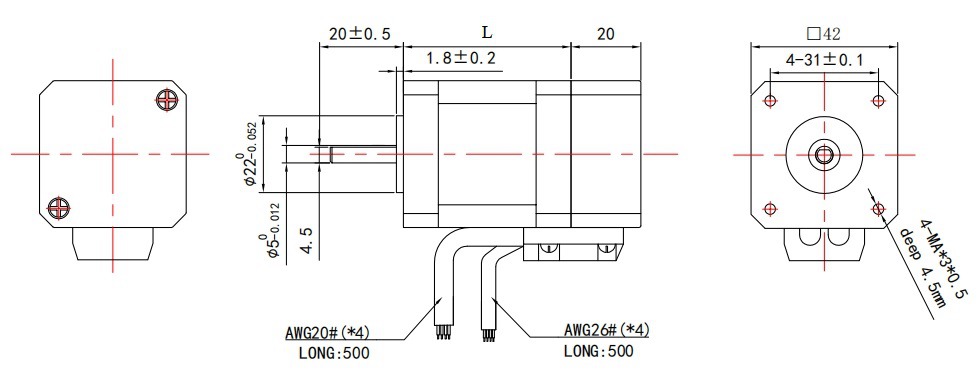

Closed-loop stepper motor nema 17

Nema 17 encoder specifications

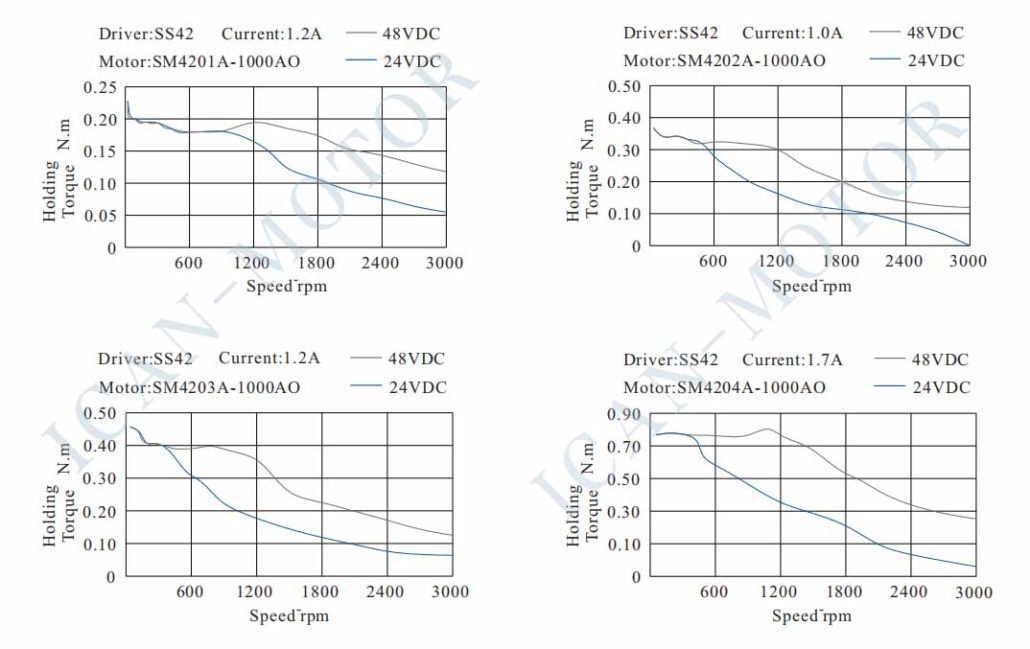

| Flange size | Models | Phase | Holding Torque(Nm) | Current phase(A) | Phase inductance (Mh) | Resistance (Ω) | Motor length(Mh) | Matched driver | Drawings Download |

|---|---|---|---|---|---|---|---|---|---|

| Nema17(42*42mm) | SM4201A-1000AO | 2 | 0.25 | 1.2 | 4.8 | 3.2 | 54 | SS42 | |

| SM4202A-1000AO | 2 | 0.35 | 1.0 | 9 | 5.7 | 60 | SS42 | ||

| SM4203A-1000AO | 2 | 0.46 | 1.2 | 6 | 3.5 | 68 | SS42 | ||

| SM4204A-1000AO | 2 | 0.75 | 1.7 | 5 | 2.5 | 80 | SS42 |

We have closed loop stepper motor from nema 17-nema23. We can also offer motor customization. Contact us for more details.

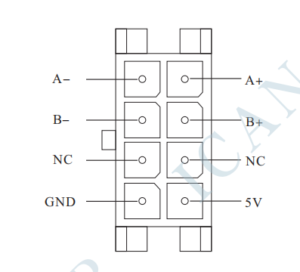

Closed loop stepper motor nema 17 port description

The motor has two cables, the motor cable&encoder cable:

Motor port:

A+/- is motor phase A+/-; B+/- is motor phase B+/-

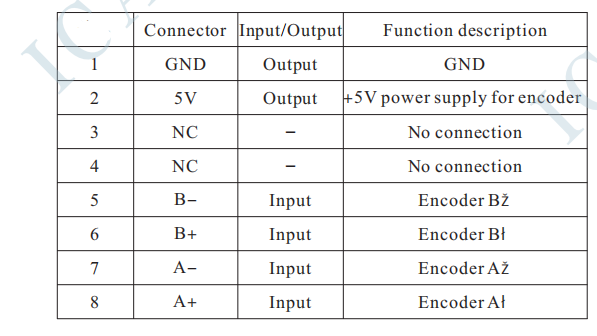

Encoder port:

A+/- is encoder phase A+/-; B+/- is encoder phase B+/-

Torque curve

Industry-leading algorithm

The SS42 closed loop nema 17 motor driver uses a high-characteristic

photoelectric encoder to feedback the position to the Cotex-M4 ARM

core processor. The position is adjusted in real-time every 50us, and

it can respond quickly to position commands. The position response

speed is better than that of various types that have appeared on the

market for many years. It can make the equipment have higher processing

accuracy, higher-finish, and more perfect product details.

Automatic current adjustment

The SS42 closed-loop stepper motor driver can automatically adjust

the step length and automatically adjust the current according to the

load. Under low load conditions, the current is automatically adjusted

to the lowest level, thereby reducing motor noise and heat. When the

load is suddenly increased, the current is fast and real-time Adjust to

the optimal value to maintain high-precision position control and

high-speed operation without losing a step.

The motor stops stably without any shaking

The SS42 closed-loop stepper motor driver continuously feedbacks

through the encoder to detect the difference between the reference

position and the actual position. When the closed-loop stepper motor

reaches the target position, it stops stably without any vibration and

becomes the series of SS hybrid servo motors (closed-loop step Into

the motor) is one of the biggest advantages different from the

traditional servo motor.

No need for parameter tuning design

The closed-loop stepper motor driver is simple to use and

doesn’t require parameter settings. The traditional servo position

PID algorithm needs to adjust the control parameters according

to the load to produce the best control effect. The tuning process

is complicated. The SS42 closed-loop stepper motor driver realizes

the fast positioning of the closed-loop stepper motor through precise

step adjustment technology, almost no need Tuning the control

parameters of the position loop avoid the trouble of parameter

setting adjustments during customer use.

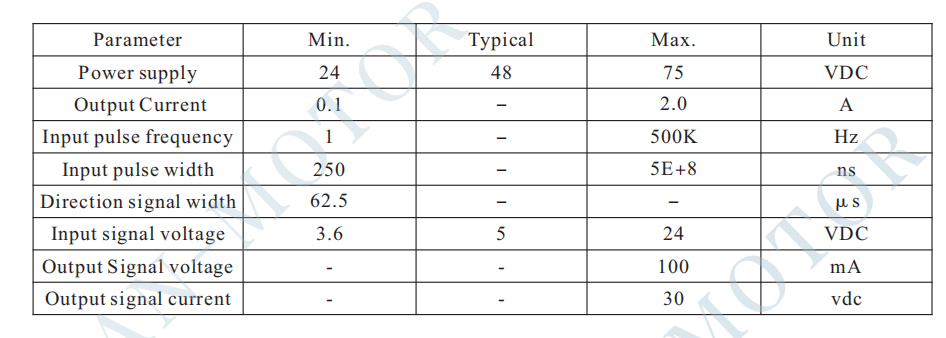

Electrical Specifications

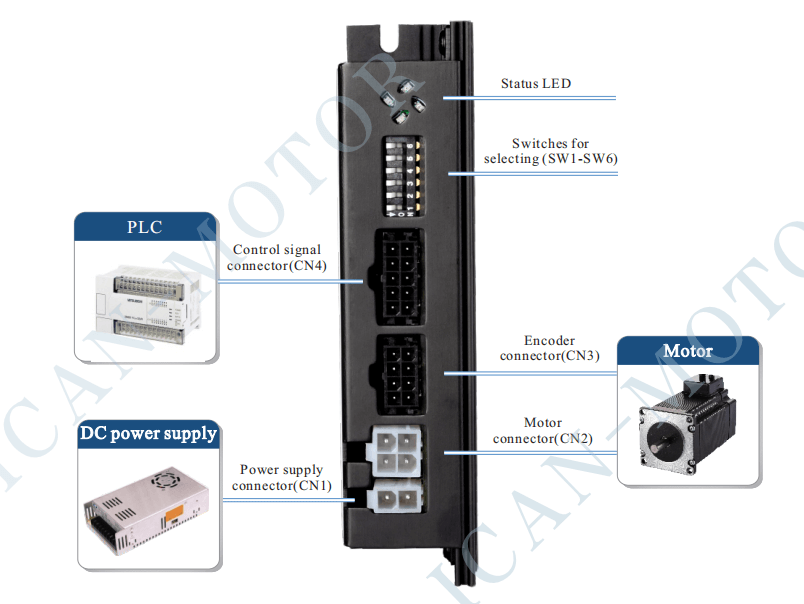

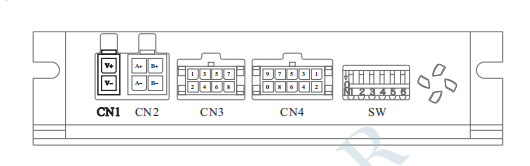

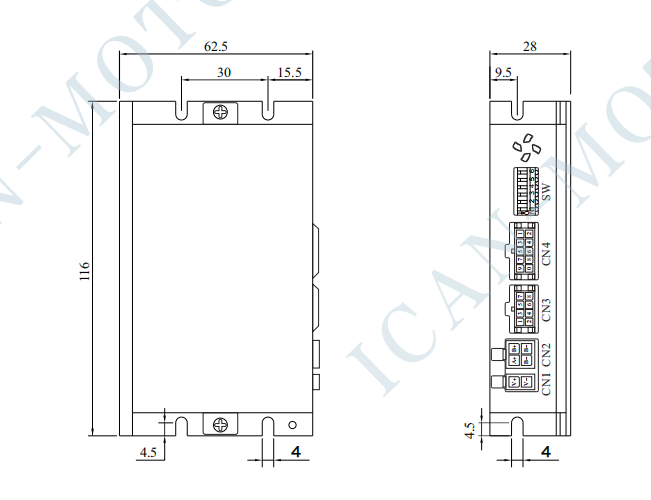

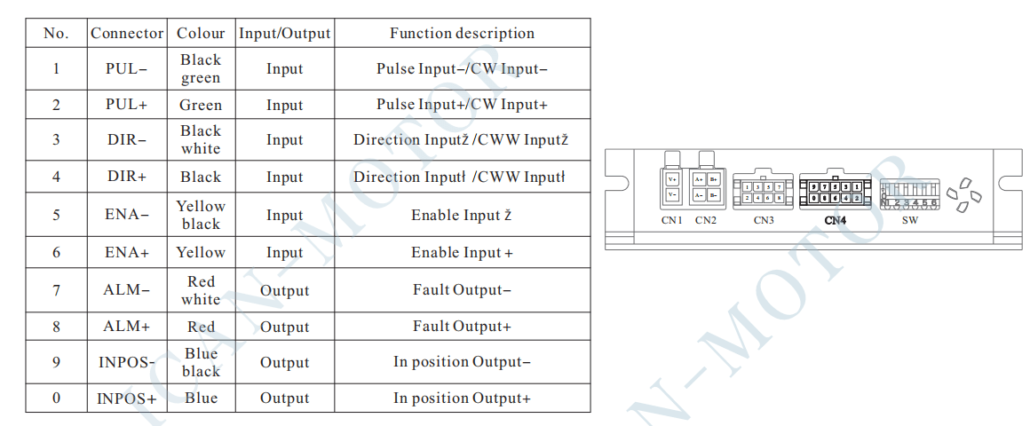

Drive interface and wiring diagram

CN1: Power supply connector. The power supply is 24VDC-75VDC.

CN2: Motor connector

CN3: Encoder connector. The feedback signal from the encoder of the closed-loop stepper motor will be put into A+, A-, B+, B-.

CN4: Control signal connector: the pulse, direction, enable signal input.

SW1-SW4: Micro stepping setting

SW5: Initial direction selection

SW6: Single/double pulse matching