Brushed v brushless motor

When designing compact motor drive programme , the first choice user makes is between brushed and brushless dc motors.

Undoubtedly, both types of motors have advantages and disadvantages, but which type is more suitable for specific applications? It requires analysis of characteristics of both type.

First, service life

The mechanical reversing system of the brushed motor directly affects its service life. The reversing system is directly affected by the load condition. The large current, high speed, reverse motion and high strength vibration generated during operation will reduce its service life.

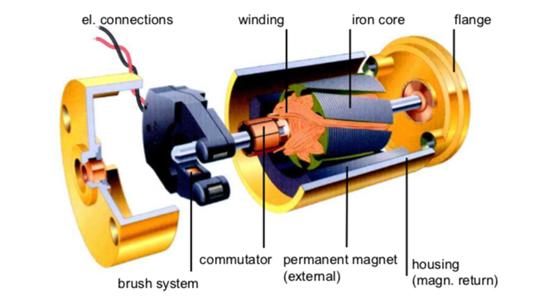

Brushed motor

The brushless motor used an electronic reversing design instead of a mechanical reversing design, which greatly prolongs motor life and reduces maintenance. Moreover, the life of the motor can be predicted relatively accurately. For example, ball bearing will limit the service life of the motor, and the service life of the motor can be accurately inferred through the design life of the bearing.

Brushless motor

Secondly, motor speed

Because of reversing system, the speed of brushed motor is generally less than 10,000 rpm. In over speed operation, the service life of the motor will be greatly shortened due to the increase of electrical and mechanical wear.

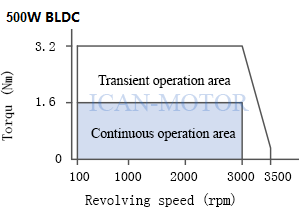

Brushless motors of the same size and magnetic structure can operate at higher speeds, even more than 100,000 rpm.

Thirdly, use environmental conditions

Brush reversing systems may generate sparks that can cause electromagnetic interference. Graphite dust from brushes can contaminate clean rooms, vacuum or optical applications.

At last,Motor control and operation

Brush motor is easy to operate, as long as the voltage is enough, the motor can start to work.

While BLDC motor requires additional electronic reversing control equipment and more complex wiring. But in applications which precise control is needed, the cost and wiring is the same for both types. With BGM’s brushless motor kits, the wiring can be done in 1 second, and speed can be adjusted by the knob easily. What’s more, the price of this bldc motor kits is low, as we cut down reductant function to save cost.

To sum up,

BLDC motor is more adaptable to different environmental conditions. It has longer service life , and has advantages on high speed applications.

In simple drive applications, the wiring and cost of brushed motors are more dominant, and the two are similar in precise control situations.

Of course, the final choice also needs to be considered in all aspects according to the specific application scenario.