Stepper motors are coming on the China-Europe train!

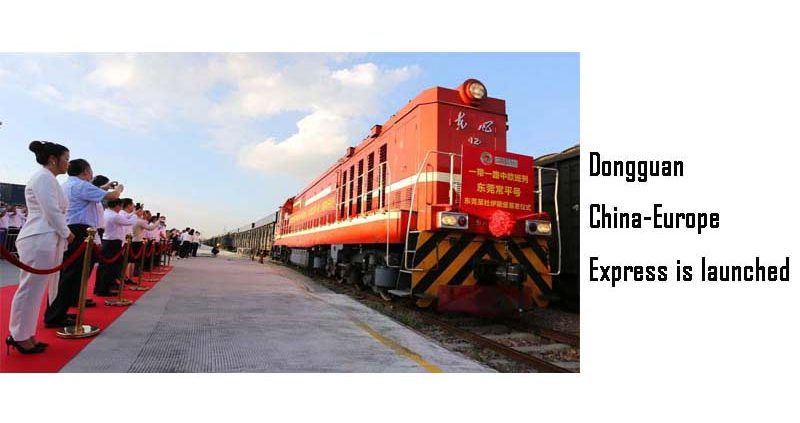

The “Dongguan Changping” China-Europe Express is launched!

At 16:30 on November 18, a railway container train with the words “Dongguan Changping” slowly left the Changsheng freight yard, marking the official launch of the China-Europe train with Dongguan Changping as its departure station.

The opening of the “Dongguan Changping” China-Europe Express is an important milestone in the construction of Dongguan’s transportation hub. It will provide more convenient channels for Dongguan manufacturing to “go out” and to “ship in”, and will surely lead Dongguan the high-quality development of foreign trade and economic cooperation.

Witnessed by the participants, the “Dongguan Changping” China-Europe train, which was loaded with electronic products, stepper motors, anti-epidemic supplies, furniture, hardware, and other goods worth more than 3 million US dollars, slowly departed from the Changping departure station and will pass through the Alashan Port. Departing, passing through Kazakhstan, Russia, Belarus, Poland, and other countries, and finally arriving in Duisburg, Hamburg, Germany. It will only take 15days to arrive.

As a Dongguan stepper motor supplier, convenient transportation will give us more opportunities to serve customers. Our high-quality motors can quickly reach customers all over the world quickly.