Closed loop vs open loop stepper motor

The stepper motor system is the foundation of the motion control industry. It has a long history from PWM driver and microstepping to digital signal processors (DSPs) and anti-resonance algorithms. Now, new closed-loop stepper motor has become a new trend.

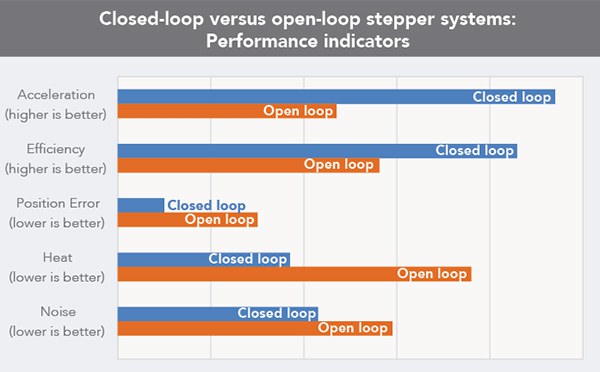

Closed-loop stepper motors is a stepper motor with encoder feedback. They achieve precise position and speed control by using position feedback sensors. Compared to open-loop stepper motors, closed-loop system have significant advantages in terms of acceleration, efficiency, position precision, heat generation, and noise level.

Higher Acceleration

Closed-loop stepper motors have higher acceleration due to their feedback mechanisms, such as encoders or Hall sensors. They detect speed and position and feed the results to the controller, which adjusts the current signal to keep acceleration within the preset range.

Stepper motor open loop control lacks real-time feedback and can’t precisely control acceleration. Stepping errors occur if the input signal is incorrect or the load changes, reducing acceleration and accuracy.

Efficiency

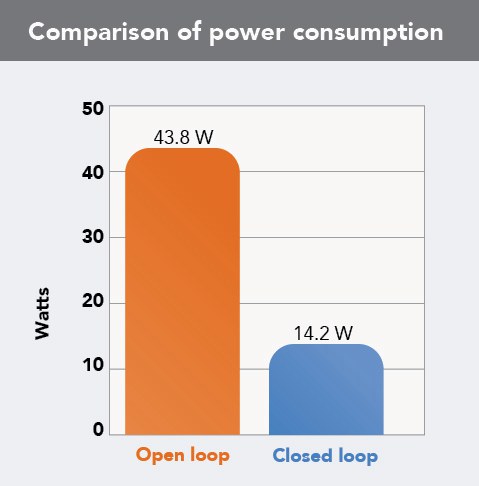

Closed-loop stepper motors have higher efficiency compared to open-loop systems, as shown by experimental data. The average power consumption of the open-loop stepper system is one-third of the closed-loop stepper system. This significant difference in power consumption indicates a higher efficiency of the closed-loop system.

Reduced Heat Generation

Closed-loop stepper motors can adjust the driving current in real-time according to changes in the load, avoiding excessive current passing through the motor and reducing the motor’s heat generation. In contrast, after setting the driver to the motor’s rated current, open-loop stepper motors will continuously supply the current to the motor, regardless of the load and required torque, which usually leads to high heat generation. The significant reduction in motor heat generation means that machine manufacturers can reduce component costs because of no need of additional protection and cooling subsystems.

Noise

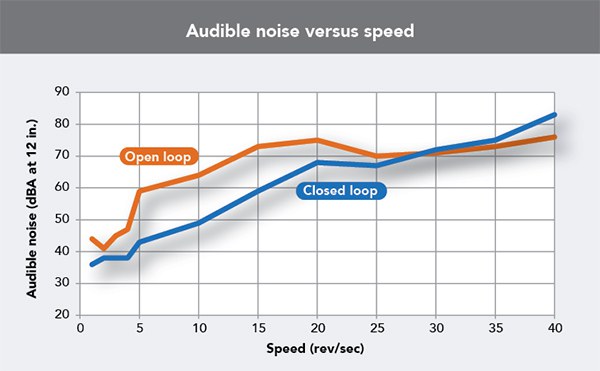

Another common issue with open-loop stepper systems is noise, as they are known to produce a lot of audible noise. In some environments, such as laboratories, hospitals, and offices, this noise can cause problems.

In a closed-loop system, the controller can dynamically adjust the motor’s current to control its operation by monitoring the motor’s movement and load. This precise control can reduce the vibration and noise generated by the motor due to overload or underload.

In the test, the noise of each system was measured in a soundproof room. Compared to speeds of 0 to 20 rpm, closed-loop systems are much quieter than open-loop options. This speed range matches the actual application speed range of most stepper motor , meaning that most stepper motor applications can benefit from the reduced noise by switching to a closed-loop system.

Improved Precision and Position Accuracy

Closed-loop stepper motors can achieve greater precision and position accuracy by using encoder feedback in the position loop to achieve servo control. In this way, the closed-loop system can automatically compensate for increased torque demands, avoiding position errors caused by increased torque demands in open-loop systems. This design greatly improves the accuracy of the entire system, especially for applications that require high-precision dynamic control, such as pick-and-place systems and 3D printers.

Upgrading Stepper Systems

The addition of high-performance feedback devices is the main cost difference between open-loop and closed-loop stepper systems. However, with technological improvements, the prices of these devices are becoming lower, making closed-loop stepper motor systems more accessible to a wider range of applications. Additionally, the energy-saving of closed-loop systems quickly offsets the slight increase in feedback device costs, making closed-loop stepper motor systems a cost-effective choice for many applications.

In conclusion, closed-loop stepper motor systems provide numerous benefits, including greater accuracy, reduced motor noise, and improved system performance. As technology continues to advance, the cost of these systems will continue to decrease, making them more accessible to a wider range of applications.