Types of brushless dc motor

There are kinds of brushless motors on the market. Types of brushless DC motors vary in their power, voltage, control technology, and installation mode, providing a wide range of options for various applications.

1. The power of the BLDC motor ranges from tens of watts to several kilowatts. P(W)*10= rated speed * torque. For example, a 70W bldc motor is often used for house cleaner, while 200-400w bldc motors are usually used in conveyors, packing machines and so on. Large stepper motor such as 750-1500w are usually found in industrial automation production line.

Bldc motor in conveyor

2. Rated voltage. According to voltage, BLDC motor can be classified as 12V BLDC motor, 24V BLDC motor, 48V BLDC motor, 110VAC and 220VAC BLDC motor and so on. Dc power supply is suitable for mobile devices and devices with high-security requirements, such as entertainment facilities. While AC power supply is easier to obtain.

3. Brushless motor flange sizes. The brushless motor has flange size of 42*42mm, 60*60mm, 90*90mm,110*110mm and so on. It can also be customized according to customer requirements.

4. Control technology. There are square wave control, sine wave control, FOC, and encoder control.

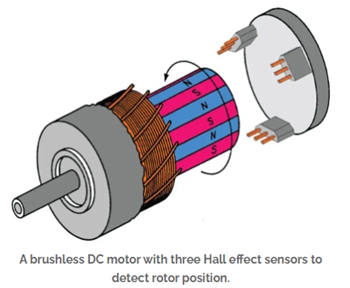

5. Product structure. BLDC motor can be divided to with hall, without hall, and linear hall. At present, the most common product in the market is the brushless motor with hall sensor, which is also main product of ICAN. After adding a hall senor, the speed and torque of BLDC motor is increased.

6. Installation mode: panel, case and embedded. If BLDC motor driver is with panel, It’s easier to for the user to control. For example, Ican’s BGM series bldc motor kits, the speed can be adjusted by the knob. On the panel with display, users can get speed, current information and so on.When the driver is placed in case, user should open the case to adjust the driver, such as ICAN BLDC-750,BLDC-300. Sometimes, the BLDC driver is without shell, and embed to user’s system.

BGM series BLDC motor kits

7. The combination of motors and other components. Brushless motors are often combined with reducer, brake or other components. Brushless motor with reducer is called gear motor. The most common gear motors are with gearbox, planetary gearbox , L type reducer, right-angle reducer and turbine reducer.

BLDC motor with planetary gearbox

8. Rated speed. There are many kinds of motors with different speeds on the market, such as 1500rpm, 3000rpm, 4000rpm and 6000rpm. Most of ICAN’s products are 1500, 3000 rpm motors.

9. The number of poles. According to the number of poles, BLDC motor can be divided into 2 pairs , 4 pairs , 5 pairs of poles. The driver pole log setting should be consistent with the motor pole log, otherwise the motor cannot operate normally.

10. Type of input signal source. There are four types of brushless motor signals:

- Analog signal. Analog signals can be build-in or external input. If it is external, it requires PLC to output analog signal. Or an extra module is necessary to output analog signal to the controller.

- Pulse frequency. Similar to stepper motor speed control, the speed of the BLDC motor is controlled by the pulse frequency.

- The motor speed is controlled by adjusting duty ratio. Duty ratio is the proportion of time of high level in a pulse cycle.The motor rotates at high level and stops at low level.

- Communication method. Communication signals are often used in multi-point control situations. RS485 and CANopen are commonly used recently. ICAN also has many controllers with RS485 70W-1500W for customers to choose.

In conclusion, the diverse array of brushless DC motor types available in the market today enables industries to find tailored solutions that meet their specific requirements. As technology continues to advance, these motors will undoubtedly play an important role in motion control .