What are types of gear box?

The reducer is an independent transmission device between the prime mover and the working machine, which is used to reduce the speed and increase the torque to meet the working requirements. In some cases, it is also used to increase speed and becomes a speed increaser.

According to the transmission type, the reducer can be divided into gear reducer, worm reducer, planetary reducer, and combinations of them. Reducers can be roughly subdivided into the following categories:

Worm gear reducer, planetary gear reducer, harmonic drive gear, Cycloidal pinwheel reducer, RV reducer, three-ring reducer, continuously variable transmission (CVT).

Below is the introduction of the most commonly used reducers.

1. Worm gear reducer

Worm gears are commonly used to transmit motion and power between two interleaved shafts. The worm gear and worm are equivalent to gears and racks in the intermediate plane, with the worm resembling a screw. To improve efficiency, the worm gear is usually made of non-ferrous metals (such as tin bronze), while the worm is made of harder steel (such as 45 steel or 40Cr).

Features:

Has a reverse self-locking function

Can achieve large reduction ratios

The input shaft and output shaft are not on the same axis or plane

Transmission efficiency is not high

Accuracy is not high

Application: high reduction ratios and efficient power transmission in various applications, including conveyors, packaging machines, material handling equipment, and other industrial applications that require slow and steady speed reduction.

2. Planetary gear reducer

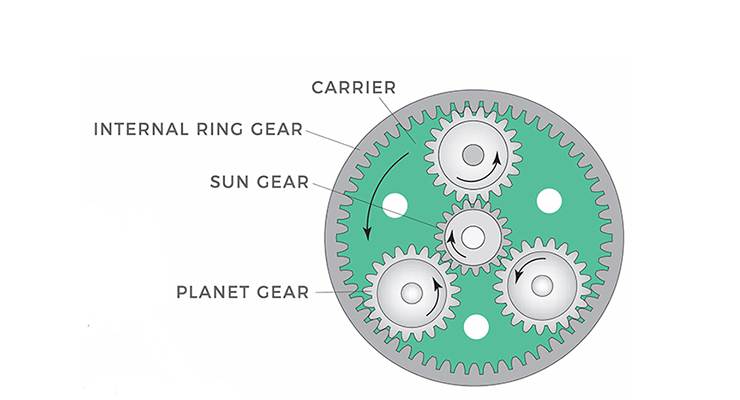

The structure of the planetary gear reducer consists of an internal ring gear tightly connected to the gearbox housing, the center sun gear driven by external power, and a set of planetary gears equally divided and combined on a carrier tray between the two. The planetary gear set is supported by the output shaft, internal gear, and sun gear. When the power is input to drive the sun gear, the planetary gears rotate and move along the trajectory of an internal gear while revolving around the center of the gear. The rotation of the planet drives the output shaft connected to the tray to output power. The main transmission structure of the planetary reducer is planetary gear, sun gear, and inner ring gear.

Features:

Small size, lightweight, high load-carrying capacity.

Small backlash, high precision.

Smooth operation, low noise, and long service life.

Large output torque, large speed ratio, high efficiency, safe performance, and maintenance-free for life.

The maximum input power can reach 104kW.

The minimum single-stage deceleration is 3, and the maximum generally does not exceed 10. The common deceleration ratio is 3.4.5.6.8.10.

The number of stages of the reducer generally does not exceed 3, but some customized reducers with large reduction ratios have 4 stages of reduction.

The maximum rated input speed of the planetary reducer can reach 18000rpm (related to the size of the reducer itself, the larger the reducer, the smaller the rated input speed) and above.

The output torque of industrial-grade planetary reducer generally does not exceed 2000Nm, and the special super-torque planetary reducer can reach more than 10000Nm.

The working temperature is generally around -25°C to 100°C and d can be changed by changing the lubricating grease.

Most planetary reducers are installed on stepper motors, BLDC motors, and servo motors to reduce speed, increase torque, and match inertia.

Application:

High torque and precise motion control applications, including robotics, industrial automation, aerospace, medical equipment, renewable energy, and automotive.

3.Cycloidal pinwheel reduce

Cycloidal pinwheel reducer, also known as cycloidal gear reducer, is a type of power transmission device that uses the principles of cycloidal motion. Its structure includes an input shaft with an eccentric double bearing called an H mechanism, which drives two cycloidal disks to rotate in opposite directions. The pinwheels, with needle-like teeth, mesh with the cycloidal disks to produce a reduction ratio. This type of reducer is known for its high torque capacity, compact size, and low noise and vibration levels. It is commonly used in industrial machinery.

4. RV reducer

The RV reducer consists of a planetary gear reducer as the first stage and a cycloidal pinwheel reducer as the second stage. The RV reducer is a compact and high ratio transmission mechanical device. It has a self-locking function under certain conditions and is one of the most commonly used reducers with low vibration, low noise, and low energy consumption.

Features:

Wide range of transmission ratio

With high torsional stiffness, the output mechanism is a two-end supported planetary frame, which uses the rigid large disk on the left end of the planetary frame as the output. The large disk is connected to the working mechanism with bolts, and its torsional stiffness is far greater than the output mechanism of a general cycloidal pinwheel planetary reducer.

Small elastic backlash under rated torque; with a reasonable design and precise manufacturing and assembly, high precision and small clearance backlash can be achieved.

High transmission efficiency.

5. Harmonic drive reducer

A harmonic drive reducer consists of a wave generator, a flexible wheel, and a rigid wheel. It usually adopts the form a of wave generator as the active component ent, a rigid wheel as the fixed component, and a flexible wheel as the output component. The rigid wheel usually has two more teeth than the flexible wheel. Through the so-called misalignment movement, motion transmission and reduction are achieved.

Features:

Low noise and high precision

High reduction ratio: A high reduction ratio of 30-320 can be achieved with a single-stage coaxial harmonic drive.

Easy installation: Three basic components achieve a high reduction ratio, and they are all on the same axis, so the kit is easy to install.

Limited service life and poor impact resistance of flexible couplings.

Compared with rigid and metallic components, the flexibility is relatively poor, and the input speed cannot be too high.

In conclusion, reducers are essential components in industrial equipment that are used to reduce speed and increase torque. There are several types of reducers. Among them, planetary and worm reducers are recommended for their features and applications. Planetary reducers are used for high torque and precise motion control applications, including robotics, industrial automation, aerospace, medical equipment, renewable energy, and automotive. While worm reducers are used for high reduction ratios and efficient power transmission in various applications, including conveyors, packaging machines, material handling equipment, and other industrial applications that require slow and steady speed reduction.