Characteristic and maintenance of brushless DC motor

Brushless DC motors are highly favored due to their compact size, lightweight design, and spark-free operation, making them ideal for use in explosive environments. In this article, we will explore the key characteristics of brushless DC motors. And give essential maintenance tips on how to keep them running smoothly.

Key Characteristics

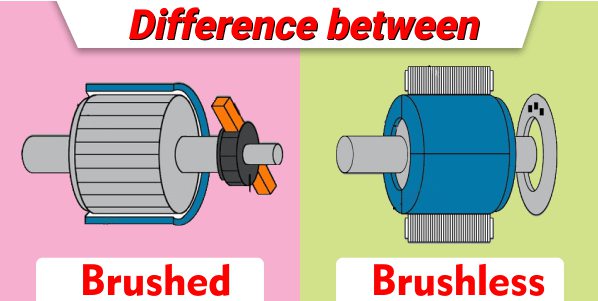

1.Can replace DC motors, frequency conversion motors, and asynchronous motors.

2.Small size, lightweight, and high torque.

3.Excellent torque characteristics, good low-speed torque performance, large starting torque, and small starting current. Visit brushless motor sets by click here.

4.Stepless speed regulation, wide speed regulation range, and strong overload capacity.

5.Soft start, soft stop, and good braking characteristics, eliminating the need for original mechanical or electromagnetic braking devices.

6.High efficiency, the motor itself has no excitation loss and carbon brush loss, eliminating multi-stage reduction losses, with efficiency up to 70%.

7.High reliability, good stability, strong adaptability, and simple maintenance and repair.

8.Resistant to vibration and shock, low noise, small vibration, smooth operation, and long service life.

9.No sparks, especially suitable for explosive environments, with explosion-proof types available.

10.Can choose trapezoidal wave magnetic field motor or sine wave magnetic field motor according to requirements.

Maintenance of brushless DC motor

1.Before disassembling, blow the dust on the surface of the motor .

2.Choose a clean working environment .

3.Learn the structural characteristics of the motor and the maintenance technical requirements.

4.Prepare the tools (including special tools) and equipment needed for disassembly.

5.To further understand the defects in the motor during operation, a test should be performed before disassembly . Therefore, the motor should rotate under load for detailed inspection of the temperature, sound, vibration, voltage, current, and speed should be tested. Then perform a separate no-load test to measure the no-load current and no-load loss and record the results.

6.Cut off the power supply, remove the external wiring of the motor, and make a record.

7.Use a megohmmeter with an appropriate voltage to test the insulation resistance of the motor. In order to compare the insulation resistance values measured during the previous maintenance to judge the trend of the insulation change and insulation status of the motor, the insulation resistance values measured at different temperatures should be converted to the same temperature, generally converted to 75℃.

8.Test the absorption ratio K. When the absorption ratio is greater than 1.33, it indicates that the motor insulation has not been dampened or the degree of dampness is not severe. In order to compare with previous data, the absorption ratio measured at any temperature should also be converted to the same temperature

In conclusion, brushless DC motors offer numerous advantages over traditional DC motors and are ideal for various applications. Proper maintenance is essential to ensure that your brushless DC motor operates optimally for an extended period. If you have any concerns or questions about maintaining your brushless DC motor, please do not hesitate to contact us.