What is a lead screw stepper motor?

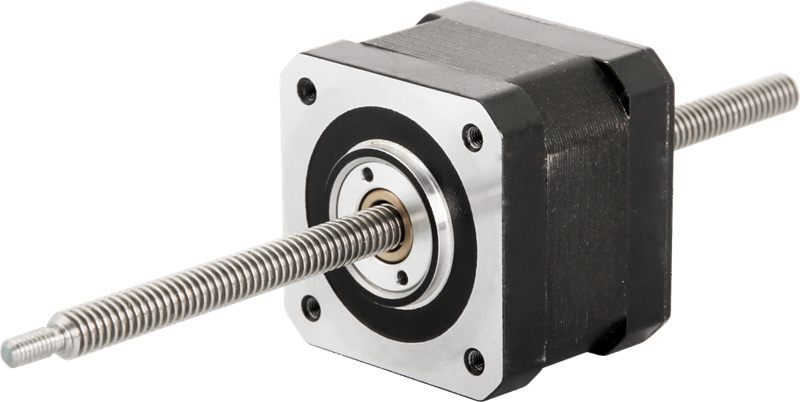

A lead screw stepper motor, also known as a stepper motor linear actuator, is a type of motor that integrates a stepper motor and lead screw. It has the advantages of small size, easy installation, and reasonable price, and belongs to the linear motion control system.

As the trend of miniaturization, refinement of mechanical equipment becomes more popular. And the use of stepper motor series products is expanding rapidly. Lead screw stepper motors are increasingly widely used in medical instruments, testing equipment, communication, semiconductor, printing equipment, stage lighting, and other related fields.

In this article, we will classify the lead screw stepper motor from its structure and briefly introduce their characteristics.

External Drive Lead Screw Stepper Motor

In a external drive lead screw stepper motor, the lead screw and the motor rotor is combined as the motor shaft, and the nut is outside the motor, converting rotary motion into linear motion. Its lead screw is generally made of stainless steel.

Below factors should be taken into consideration during use:

1.The rated current of motors is different. The driver’s current shouldn’t exceed the rated current of the motor itself, otherwise, it will easily cause serious consequences such as overheating or burning of the motor.

2. The lead screw cannot be too long. A long lead screw may bring some risks. The biggest risk is that the actuator and lead screw will produce resonance at some positions during the motion, which will cause obvious noise. Users can buy linear actuator stepper motors with a stroke of 20-1000mm from ICAN company.

Pass-Through Shaft Lead Screw Stepper Motor

The pass-through shaft linear stepper motor integrates the nut and the motor rotor into one, with the lead screw passing through the center of the motor rotor. When the motor is energized and the rotor rotates, the motor will move linearly along the lead screw. Conversely, if the motor is fixed, the lead screw will move linearly.

When using, the following should be noted:

1. Because there is no mechanical limit between the lead screw and the nut, the lead screw will slip out if it exceeds the stroke during the operation.

2. Adding other types of lubricating oil to the lead screw is unnecessary. The lubricating oil has been added to the lead screw in the factory. Using other lubricating oils will damage the motor.

Fixed Shaft Lead Screw Stepper Motor

In some applications where it is impossible to provide anti-rotation devices for nuts or screws, this type of motor can be used. Like the pass-through shaft motor, a fixed shaft stepper linear actuator is with a nut embedded in the motor body. The lead screw is connected with the key shaft which matches with the keyway sleeve at the front end of the motor to prevent rotation, thereby realizing the linear motion of the motor.

For applications that require short strokes, such as less than 50mm, and cannot provide anti-rotation devices, it is recommended to use fixed shaft stepper linear actuator. It has advantages of compact structure and no need for anti-rotation devices. The lead screw extends from the front end but not rotate.

In conclusion, lead screw stepper motors are versatile and efficient linear motion control systems that offer several benefits . Their compact size, ease of installation, and reasonable cost make them an attractive option for a variety of applications. By considering the factors outlined in this article and selecting the appropriate lead screw stepper motor, users can ensure optimal performance and achieve their desired linear motion with ease.