How to choose a worm gearbox?

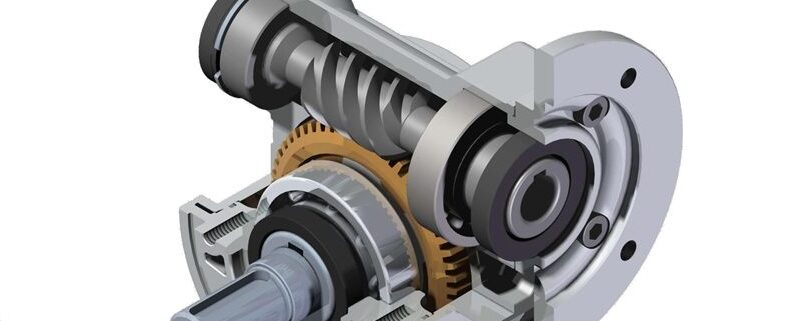

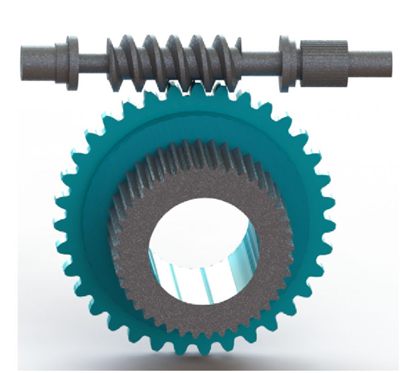

Worm gearbox is a commonly used transmission equipment in industrial production. It is a mechanical device that uses a gear speed converter to reduce the motor speed and increase torque. Before choosing a worm gear speed reducer, we should consider the characteristics of the reducer based on the production conditions and choose the worm gear reducer accordingly.

In this article, we will introduce the worm gear reducer from several aspects such as its advantages, selection methods, and precautions, and understand how to choose the right type.

Advantages of Worm Gearbox

(1) Cost-saving: Worm gearboxes with brushless motors are cheaper than planetary reducers with brushless motors.

(2) Diversified installation methods: mainly divided into vertical and horizontal types.

The vertical installation method refers to the worm axis vertical to the ground. This installation method is suitable for situations with limited space or requiring high-power output, such as in a turbine generator.

The horizontal installation method refers to the worm axis parallel to the ground. It is usually more suitable for situations with relatively spacious spaces. This installation method can reduce the center of gravity of the reducer, thereby improving the stability and safety of the entire device. This installation method is often used in car engines.

(3) Worm gearboxes have a diversified speed ratio, and the single-stage speed ratio is 5-100. This means that the worm gearbox can reduce the speed of the input shaft to 1/5-1/100 of the original, making it more suitable for equipment that requires a lower-speed operation. .

(4) Self-locking function. The self-locking worm gear means that when the worm gearboxes stops running, it can prevent the connected mechanical equipment from rotating in the opposite direction, thereby ensuring the safety and reliability of the system.

(5) The aluminum alloy shell is light in weight, which can reduce the weight of the entire mechanical device, thereby reducing the requirements for support and improving the efficiency and performance of the device.

Selection Methods of Worm Gearbox

(1) Determine the model and size of the required reducer.

(2) Calculate the right speed ratio. The speed ratio calculation method is: speed ratio = motor speed/output shaft speed of the gearbox.

(3) Determine the torque (power) of the gearbox: the torque is crucial to the life of the gearbox. The maximum torque of the gearbox shouldn’t exceed the maximum load torque.

(4) Determine the output and input shaft directions: the gearbox has horizontal and vertical types.The output and input shaft directions are:

L direction: single input and single output, the right end is the input shaft, and the front is the output shaft.

R direction: single input and single output, the left end is the input shaft, and the forward output shaft.

V direction: single input and double output, the left end is the input shaft, and the double output shaft is positive/back

W direction: double input and single output, the input shaft is on the left and right ends, and the forward output.

F direction: double input and double output, the input shaft is on the left and right ends, and the forward/backward output.

(5) The size of the input hole and input flange.

(6) The size of the output hole or output shaft

(7)Check if other accessories are needed, such as torque arms, output flanges, single/double output shafts, etc.

Precautions for using worm gearbox:

(1) Before using the worm gear reducer, check if the form and structure of the reducer, the transmission ratio, the center distance, the output shaft structure, the input shaft connection method are correct.

(2) Check the oil level before use. This can be observed through the oil level static hole or by opening the oil plug.

(3) Gradually increase the load before use, and do not start at full load.

(4) The reducer should not be exposed to sunlight or harsh environments to avoid damage to the reducer.

(6) The standard working environment temperature of the reducer should be maintained at -5℃ to 40℃.

(7) Ensure ventilation that does not affect the motor fan’s heat dissipation.

(8) If the reducer is stored for a long time, such as more than 4 months, check if the oil seal is immersed in lubricating oil and whether the oil seal has elasticity.

To summarize, worm gearboxes are widely used in industrial production due to their cost-saving advantages, diverse installation methods, and self-locking function. Proper selection and use of worm gearboxes are crucial for their longevity and reliable performance in various applications.If you want to know more about planetary gear reducers, worm gear reducers, brushless motors,and other reduction transmission products, please contact us.