What does gearbox do?

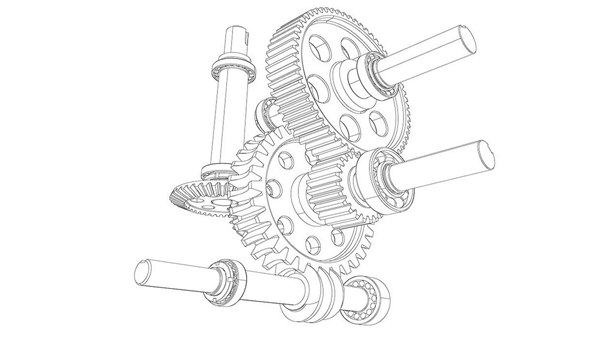

Gear is a mechanical component widely used in mechanical transmission. From small gears for clocks to large gears for conveying machines, it can reliably transmit power. Different speed ratios can be obtained by matching gears with different numbers of teeth. The position of the mutual relationship between the axes can be freely changed. It can be used for transmission between various axes such as parallel axes, intersecting axes, and staggered axes.

The gearbox functions as a device that transfer speed and torque between the motor and working machines. Motors usually include AC motors, BLDC motors, stepper motors, etc. Working machines include cranes, material conveyors, mixers, etc. The motors generally have high speed, while most working machines operate under heavy load and low speed. By meshing the gear with a small number of teeth on the input shaft with a larger gear on the output shaft, the gearbox (gear reducer) reduces speed and increases torque.

What are the types of gearboxes?

There are three types of gearboxes according to the gear axis: parallel shaft, intersecting shaft, and staggered shaft.

Parallel shaft gears include spur gears, helical gears, helical racks, internal gears, etc.

The intersecting shaft gears include straight bevel gears, zero-degree bevel gears, curved bevel gears, etc.

Staggered shaft gears include staggered shaft helical gears, halberd gears, worm gearboxes, etc.

What are the Characteristics of the Gearbox?

1. Reduce the speed and increase the torque

In practical use of the motor, when considering other functions and requirements, it is difficult to only use the rated speed of the motor. So it is necessary to reduce the motor speed, and a reducer is often used. While decelerating, the reducer will increase the output torque of the motor. Commonly used geared motors are brushless planetary geared motors, brushless dc motors with gearboxes, stepping planetary geared motors, stepping motors with gearboxes, closed-loop stepping planetary geared motors, AC geared motors, etc.

2. Reduce the inertia of the motion mechanism

In the design and development of mechanical structures, It is usually necessary to consider whether the inertia of the moving equipment matches. If not, the stability of motion, accuracy, and service life of the device will be reduced. It is not advisable to increase the motor without limitation to match the motion inertia. Therefore, this problem can be solved by adopting a reducer.

3. The reducer can effectively improve the accuracy

High-precision low-speed motors are expensive. But the combination of a high-speed motor and gearbox will reduce the transmission error during the deceleration, and the price is low. For example, the common combination is a brushless DC motor with a planetary gearbox.

4. Locking mechanism

The reducer has a very important function, which is the locking function. For example, the worm gear reducer has a self-locking function. When its reduction ratio reaches a certain ratio, it can almost completely shield the reverse impact of the working machinery on the motor, and even completely stop machinery motion. Many mechanical structure design engineers think that every worm gear reducer has a locking function. But in fact, the worm gear reducer only has the self-locking function at a certain reduction ratio. This speed ratio needs to reach, 30, 40, or higher.

5. Reduce production costs

As the speed reducer has the effect of reducing the speed, the motor with low power can achieve greater torque output, which achieves the effect of saving costs.

6. Optimize the mechanical structure design

Because of the use of the reducer, we can choose a motor with a smaller power, thereby simplifying our entire product design structure, so that many functional parts can be made more refined and compact, and avoid “stupid and clumsy” looking, which is also one of the reasons why mechanical design engineers are willing to choose to use reducers.

what are the applications of gearboxes?

Gearboxes are widely used in several industries such as below.

Paper industry: To ensure the smooth running of paper industry machines, paper manufacturers use different types of gearboxes made from steel, aluminum alloys, cast iron, and steel. ICAN company’s worm gearboxes are made from aluminum alloys, which have the advantage of high stability, and good heat dissipation.

ICAN worm gearbox

Steel industry: The steel industry involves highly sturdy machines. Pinion and planetary gearboxes are often used in this industry.

Sugar industry: The sugar industry is one of the biggest industries that employ a tremendous variety of gearboxes such as helical, planetary gearboxes, and others.

Cement industry: The cement industry adopts gearboxes that can carry a high torque. The two main types of gearboxes that are commonly used are bevel helical and parallel shaft gearboxes, which help in the reduction of speed and engine augmentation.

Other industries: There are other industries in that gearboxes find their usage such as packaging machinery, conveying equipment, chemical equipment, environmental protection machinery, metallurgical mining equipment, wind power generation, road construction machinery, escalator elevator drive, shipbuilding, light industry field, metallurgical industry, building material industry, hoisting machinery, conveyor line, assembly line, etc.

In a word, gearboxes play an important role in the power transmission systems. They are available in all sizes, types,and shapes, and can be mechanical or automatic. Gearboxes can also be customized depending on every industry’s requirements. ICAN company is a leading motor and gearbox manufacturer, which offers motors and gearboxes with the highest quality and customization service.